- support@balaji-engineering.com

- +91 98791 59441

Quality Assurance

About

Quality Assurance

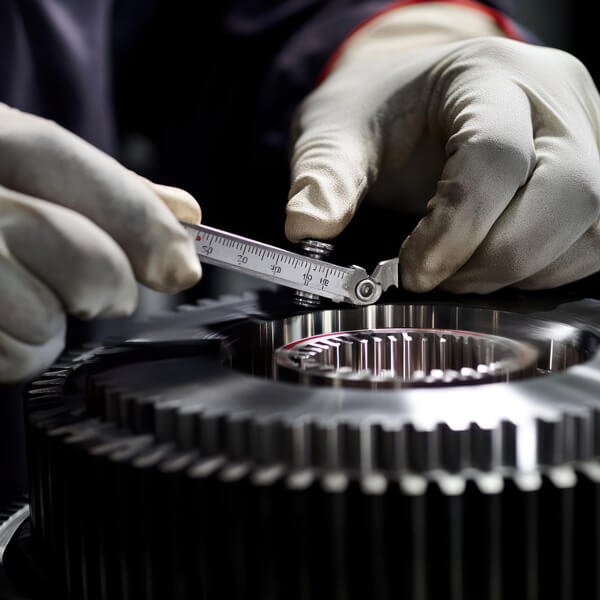

At Balaji Engineering, quality is not just a process — it is the foundation of every component we manufacture. As a trusted producer of high-precision automotive and industrial components, we follow a stringent quality management system that ensures every product meets the highest standards of performance, reliability, and durability.

Our Quality Assurance process begins at the design and development stage and continues through every phase of production — CNC machining, VMC machining, and advanced metal forging. We are committed to delivering components engineered with precision, backed with technology-driven inspection systems, and manufactured with unmatched consistency.

Quality at Balaji Engineering is built through robust validation, real-time monitoring, and customer-focused manufacturing practices.

Quality Control & Testing Infrastructure

To ensure precision and consistency, Balaji Engineering is equipped with highly advanced measuring and testing instruments. Our inspection labs and calibrated equipment help us control tolerances, material integrity, and dimensional accuracy.

Inspection

We follow a multi-stage inspection system to ensure every component meets the design and quality expectations.

We remain committed to delivering high-performance components that meet global benchmarks, exceed customer expectations, and support industries with confidence and trust.